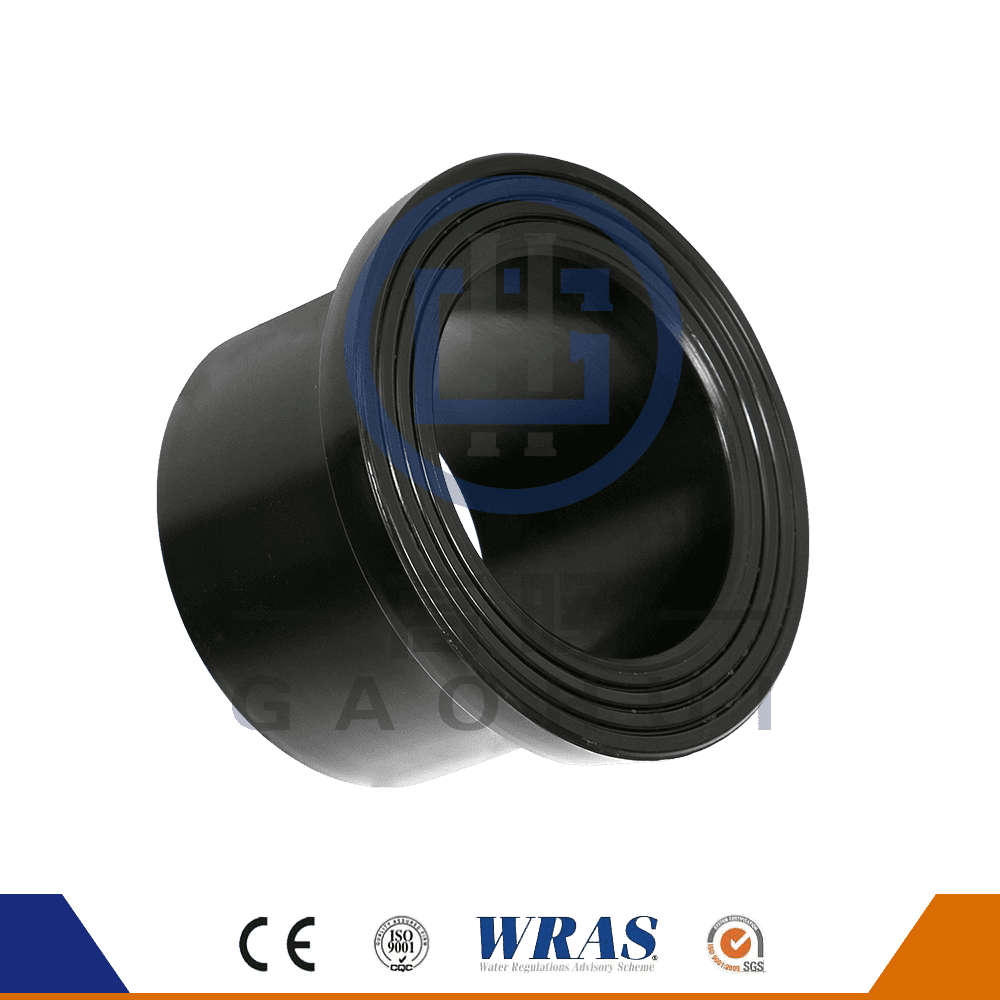

Butt Fusion technology is the most commonly used and effective way to connect HDPE (high-density polyethylene) pipes. Its working principle is to heat the pipes or pipe fittings to be connected at both ends to melt their surfaces, and then connect the two together by applying pressure to form a seamless whole. Compared with traditional connection methods such as threads and flanges, welding technology has many unique advantages, especially in occasions with high requirements for pipeline systems, it can provide more stable and reliable connections.

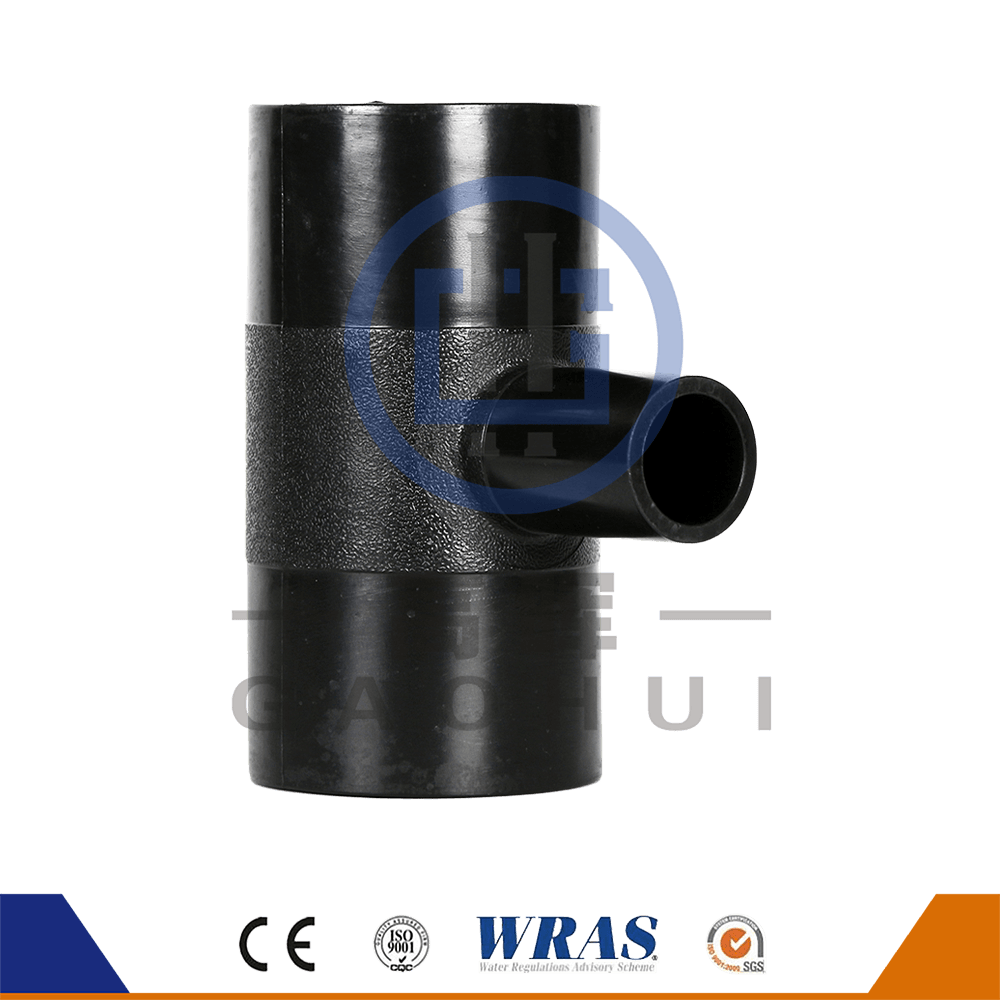

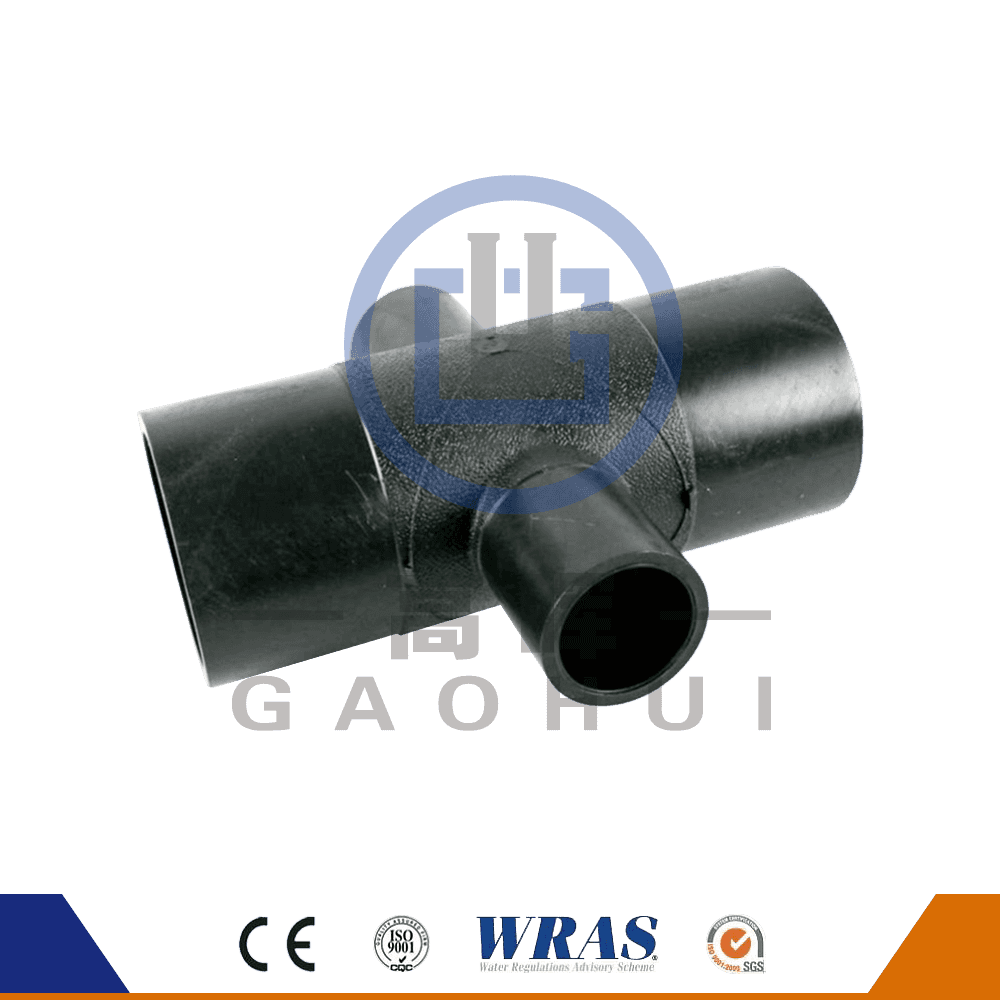

Gaohui Machinery fully utilizes these characteristics of welding technology when producing Virgin Material Of HDPE Butt Fusion WYE Tee Lateral Tee 45 Degree Y branch For Water Pipe, so that the product has stronger pressure resistance, corrosion resistance and longer service life during the pipeline connection process, meeting the high requirements of quality and reliability of different water pipe systems.

One of the biggest features of welding connection is that it can provide seamless connection. This structural design eliminates the interface problems such as seams and threads in traditional connection methods, and greatly improves the sealing of the connection parts. In the pipeline system, the joints are often the weak links for leakage and damage, especially in high-pressure and highly corrosive environments. The pipe joints connected by **Butt Fusion** have almost no gaps, can achieve complete sealing, avoid the risk of leakage, and ensure the long-term stable operation of the pipeline system.

Maintaining high sealing of joints is crucial in the fields of municipal water supply, sewage treatment, industrial pipelines, etc. With the support of fusion connection technology, Gaohui Machinery's HDPE Butt Fusion WYE Tee can provide extremely high sealing, reduce the possibility of leakage in the water pipe system, and effectively reduce the frequency and cost of repairing and replacing pipes.

Compared with traditional flange connections or threaded connections, the connection points produced by fusion technology are more solid and durable. Since the same HDPE material is used in the fusion process, the strength of the connection is almost the same as the pipe itself, which means that the pressure resistance and impact resistance of the joint part are greatly improved. In high-pressure pipelines, complex underground water pipe systems and extreme climate environments, pipeline systems connected by fusion can maintain long-term stability.

Gaohui Machinery's Virgin Material Of HDPE Butt Fusion WYE Tee Lateral Tee 45 Degree Y branch For Water Pipe uses advanced fusion technology to ensure the pressure resistance and wear resistance of the product in long-term use. The application of this technology enables the pipeline system to better withstand external pressure in harsh environments and reduces the problem of pipeline damage caused by joints.

HDPE material itself has extremely strong corrosion resistance and can effectively resist the erosion of various chemicals. The corrosion resistance of the pipeline system connected by Butt Fusion is further enhanced. Since the welded joint is a fusion of the same material and there are no external metal connectors, common metal corrosion problems can be avoided. In water treatment, sewage discharge, chemical pipelines and other places where high corrosion resistance is required, the use of HDPE Butt Fusion WYE Tee can ensure the long-term safe operation of the pipeline system and reduce the risk of pipeline aging and corrosion.

The welded connection provides a smooth and flat connection surface, which means that the water flow will not be obstructed by any unnecessary obstacles when passing through the connection. Traditional threaded or flanged connections may have protruding seams or connecting parts, which are prone to form vortices or fluid flow resistance, affecting the flow efficiency of the fluid. The pipe joint connected by welding forms a flow channel that is smooth and consistent with the inner wall of the pipe, greatly reducing the pressure loss and energy waste when the water flows through.

For municipal water supply or agricultural irrigation systems that require large water flows, reducing resistance at the connection can improve system efficiency and effectively reduce energy consumption. Gaohui Machinery's Virgin Material Of HDPE Butt Fusion WYE Tee Lateral Tee 45 Degree Y branch For Water Pipe, with its smooth fusion joints and precise design, provides customers with a more efficient water flow channel and optimizes the performance of the overall water pipe system.

Compared with other traditional connection methods, the installation process of fusion technology is simpler and more efficient. During the fusion process, construction workers only need to heat both ends of the pipe to a molten state and then apply appropriate pressure to complete the connection. No additional connectors, sealing gaskets or other auxiliary tools are required. Therefore, fusion connection greatly shortens the construction time and reduces the risks caused by improper connection.

The Virgin Material Of HDPE Butt Fusion WYE Tee Lateral Tee 45 Degree Y branch For Water Pipe product used by Gaohui Machinery does not require too many complicated processes during the installation process, which greatly simplifies the construction difficulty of the pipeline system. This undoubtedly provides a more efficient solution for engineering construction projects, especially municipal construction or temporary facility pipeline installation with tight time.

English

English русский

русский عربى

عربى