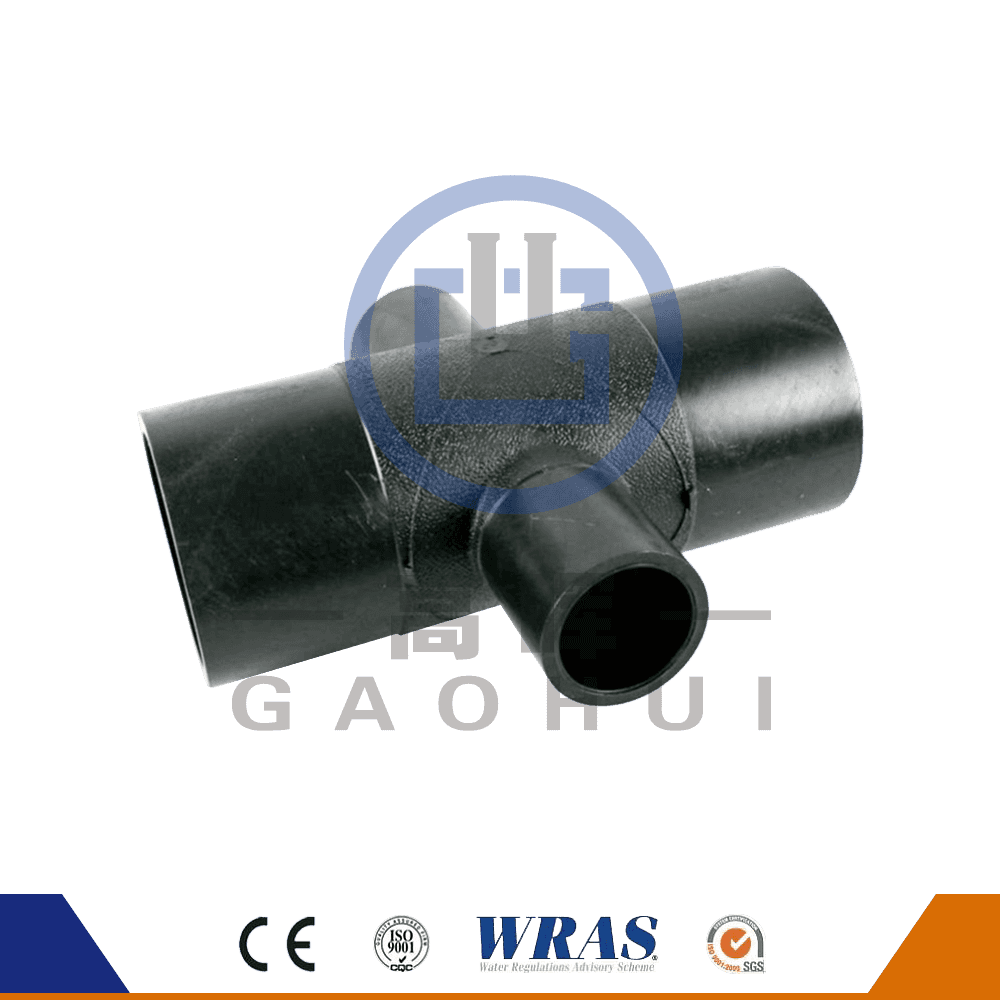

It is crucial to ensure the optimal hot melt connection performance of each product during the manufacturing process of HDPE Socket Fusion Fitting. We have implemented a series of strict quality control measures to achieve this goal. Firstly, we carefully select high-quality HDPE raw materials that have undergone rigorous screening and testing to ensure their good melt flowability and chemical stability. Secondly, we adopt advanced injection molding technology to ensure the dimensional accuracy and surface quality of each pipe fitting meet the design requirements by precisely controlling parameters such as mold temperature, injection pressure, and cooling time.

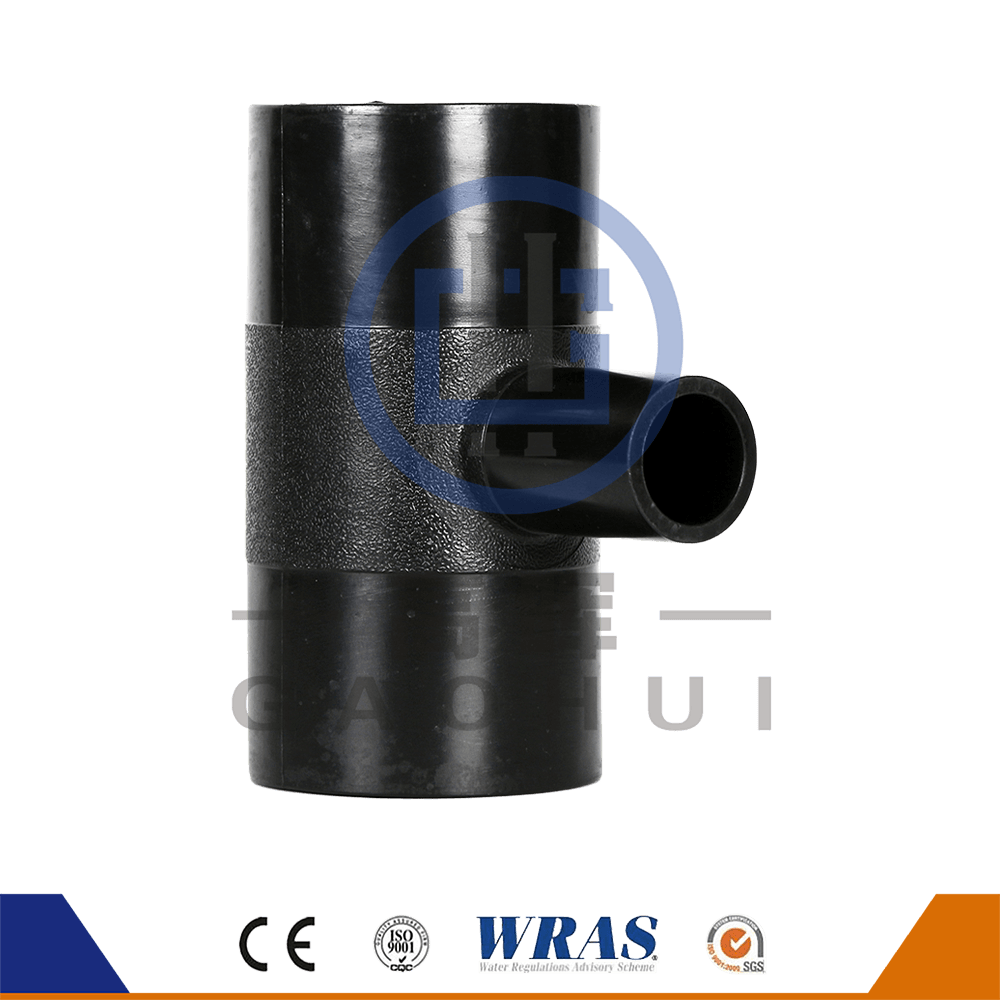

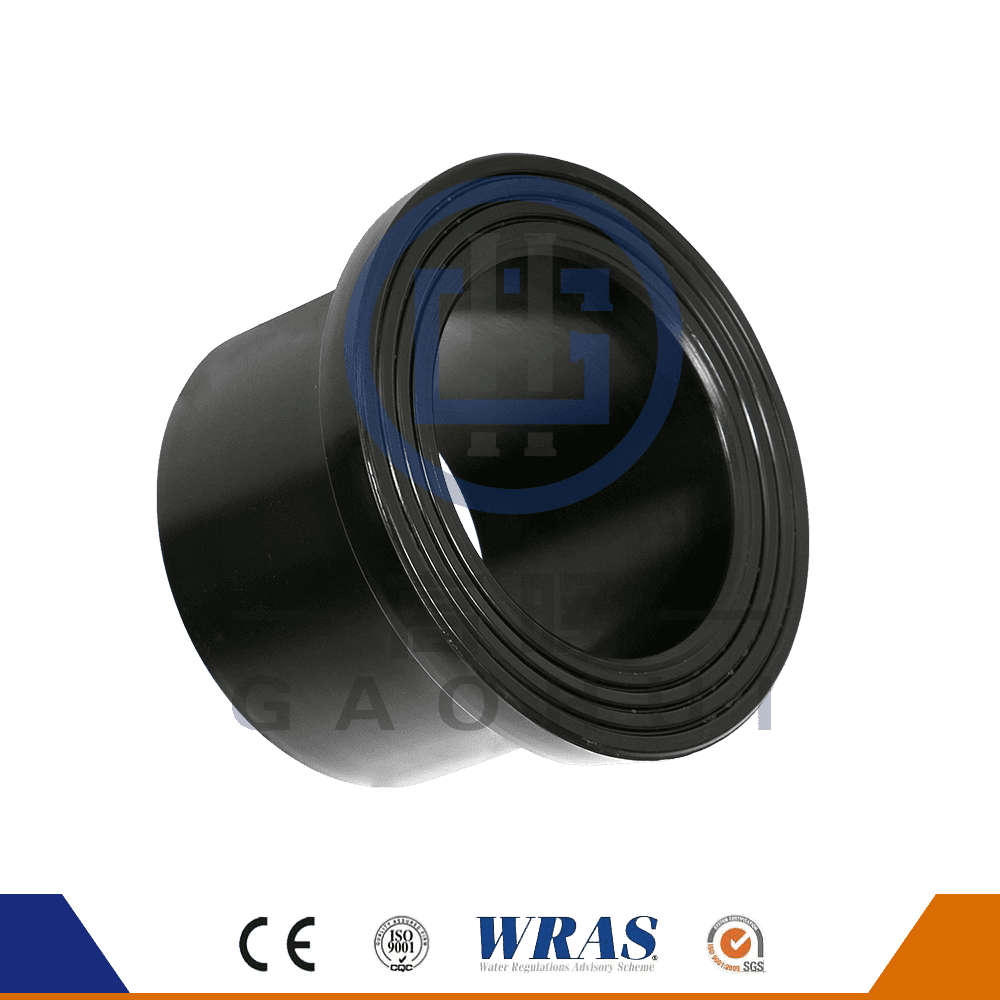

In terms of hot melt connection performance, we pay special attention to the design and production of the socket part. The socket part needs to have sufficient wall thickness and precise dimensions to form a good fusion with the end of the pipeline during the hot melt process. We use precise mechanical processing and polishing techniques to finely treat the socket part to ensure its surface is smooth, defect free, and forms a good fit with the end of the pipeline. In addition, we also conduct hot melt connection performance tests on each batch of pipe fittings, simulating actual usage conditions to verify their connection strength and sealing performance, ensuring that each product can meet customer needs.

English

English русский

русский عربى

عربى