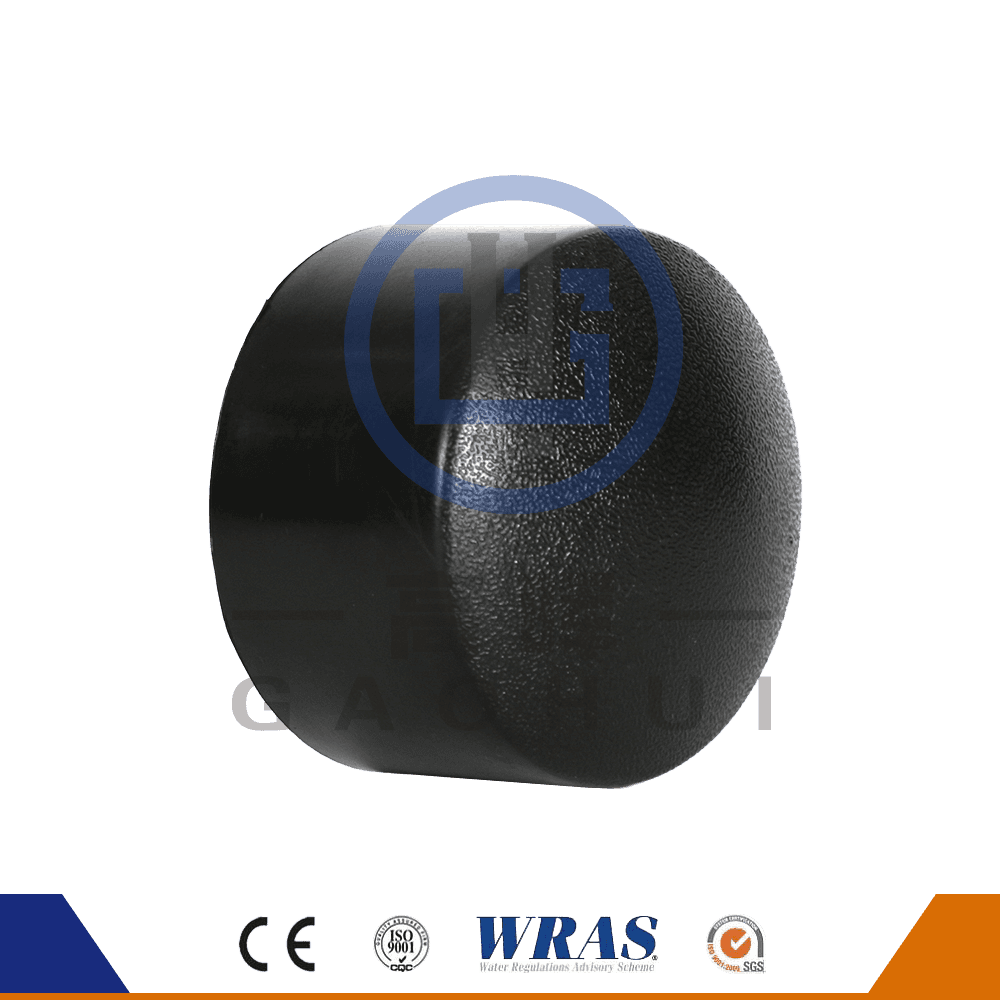

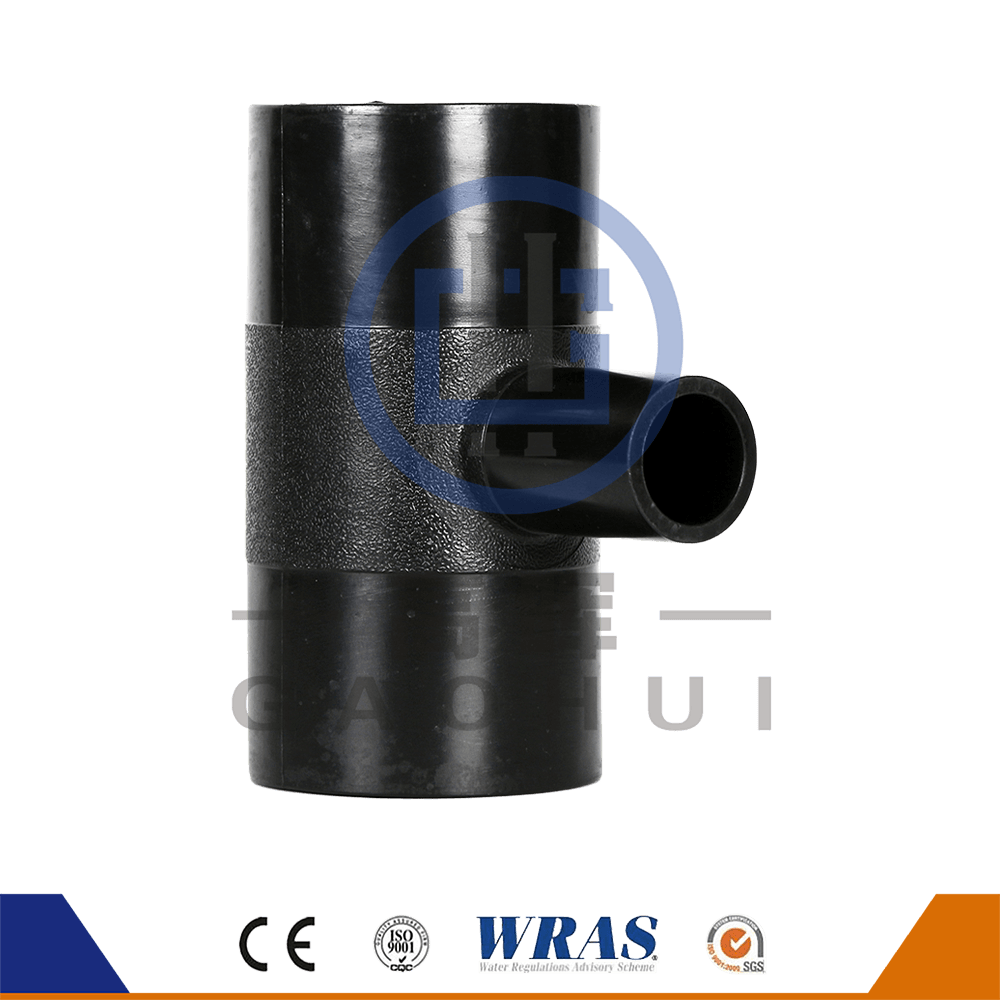

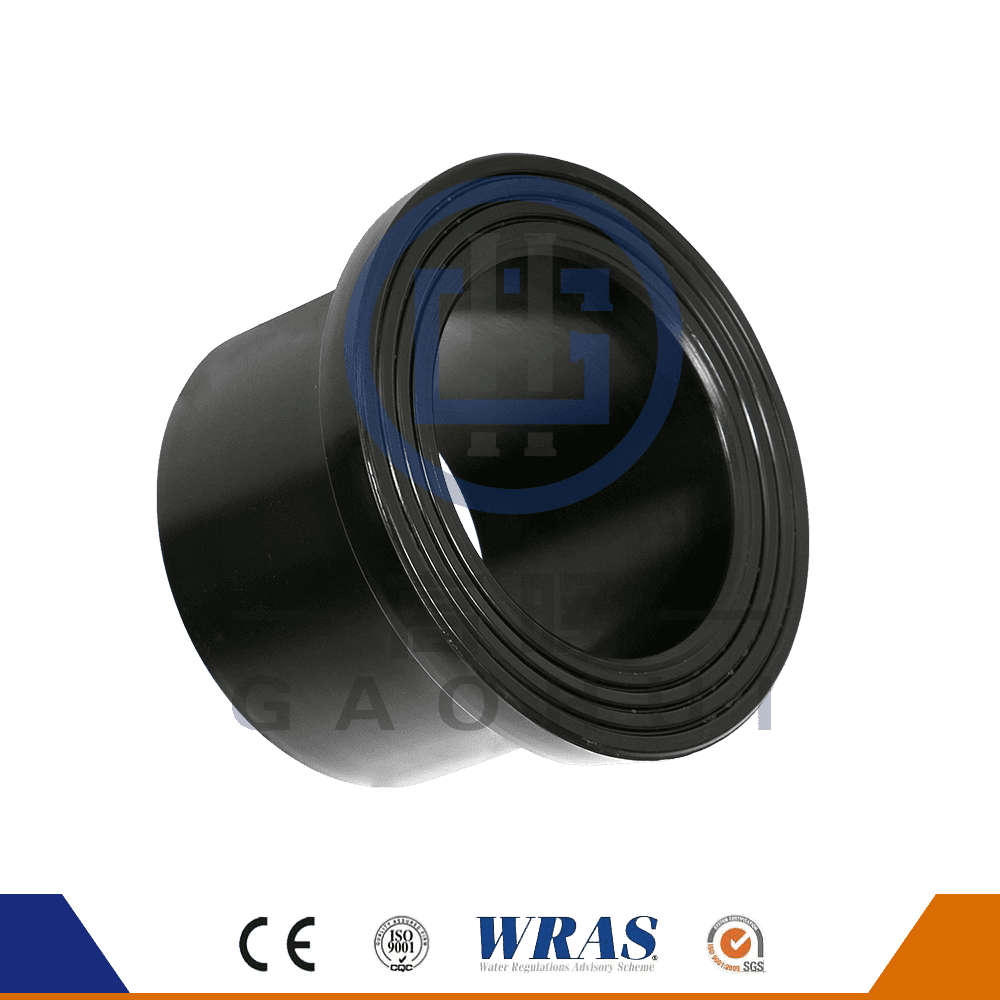

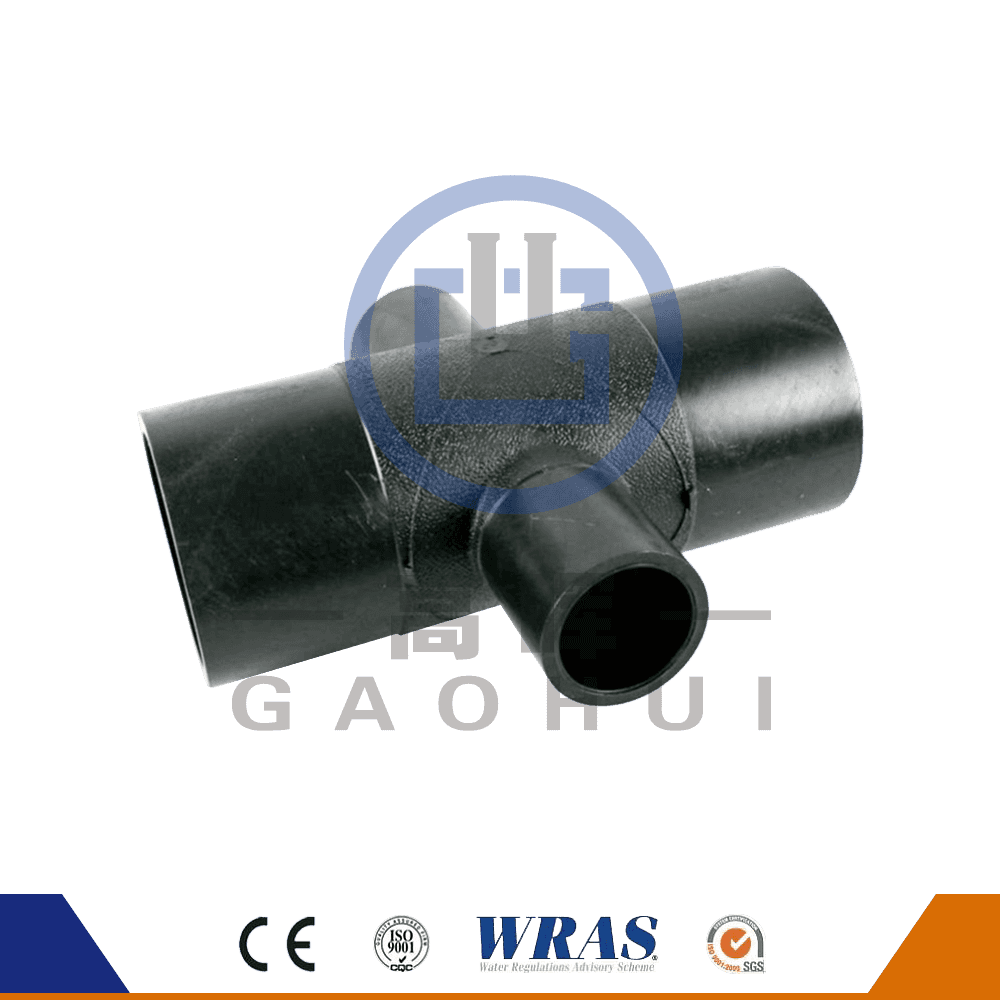

The stability and durability of HDPE Socket Fusion Fitting are particularly important in pipeline systems that deal with extreme temperature conditions. As a manufacturer, we have taken a series of special measures to ensure the performance of our products in these extreme environments. Firstly, we have chosen HDPE materials with higher heat and cold resistance, which have been specially formulated and processed to maintain stable physical and chemical properties over a wider temperature range.

In terms of product design, we have optimized the wall thickness and structure of the pipe fittings to enhance their ability to resist temperature changes and pressure fluctuations. By increasing the wall thickness of key parts and adopting structural designs such as reinforcing ribs, we have improved the rigidity and strength of the pipe fittings, enabling them to better cope with stress concentration and deformation problems under extreme temperature conditions.

In addition, we have strictly controlled every aspect of the production process to ensure that every product meets strict quality standards. Before leaving the factory, we conduct strict inspections and tests on all products, including temperature cycling tests, pressure tests, and sealing tests, to ensure their stability and durability under extreme temperature conditions. Through the implementation of these measures, we are able to provide customers with reliable and durable HDPE Socket Fusion Fitting products to meet the diverse and complex pipeline system requirements.

English

English русский

русский عربى

عربى